Imagine a craftsman working long hours to mix just the right amount of ingredients to create a translucent piece of china for a table setting, and that would be how it was done many years ago. For those interested in how the pieces they will purchase these days were created, manufacturing modern china has come a long way. Companies that create many sets of these beautiful pieces have expenses and schedules to meet, so they use slightly different methods than the craftsmen of bygone days.

Clay recipes for bone china

The recipe for making the basic china is one many companies keep closely guarded, so it is important only to know they have perfected it. Once they have reached that stage, it comes down to being able to create all the pieces they need quickly. Rather than mixing their kaolin clay recipe by hand, they have experts adding the ingredients in prescribed amounts and a particular order to create a slurry.

Using modern moulds to shape clay

Using a slurry might not sound as romantic as the old-fashioned craftsmen once worked their hydrous clay and kaolin, but it allows modern manufacturers to use moulds for their pieces. They can make an entire set of china by filling the moulds and letting them dry. Firing in an industrial kiln is the next step, and then glazing is done.

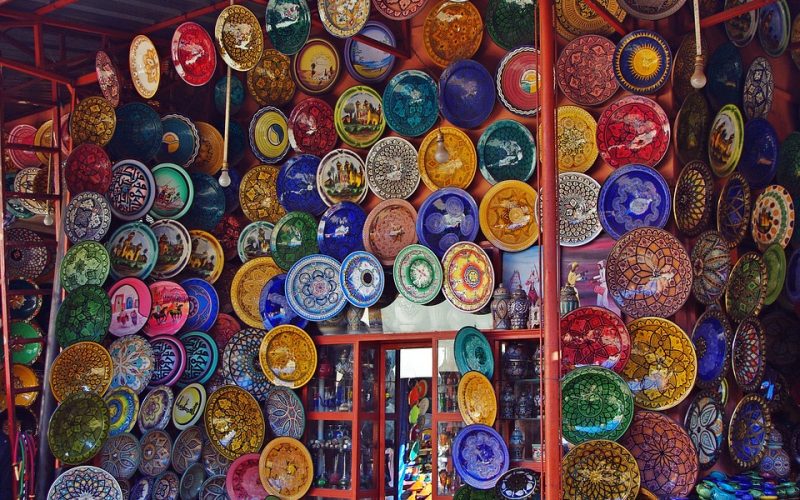

Glazing done by hand

Where many might feel not much attention is given to making their modern china set, the glazing is often still done by hand. Craftsmen and women work hard to create the beautiful patterns seen today, and they ply their craft in much the same way their ancestors did hundreds of years ago.